Antennas, Antenna Cables, Wireless Products: Technical Articles

SMA Connectors Specifications, Applications, Composition, and Characteristics

Table of Contents

- SMA Characteristics and Key Points

- SMA vs RP-SMA: A Common Source of Confusion

- SMA Male vs SMA Female: Counter-Intuitive Gendering

- SMA Connector Design and Performance

- SMA Connector Materials Composition

- SMA Male and Female Dimensions

- Panel Cutouts for SMA Bulkhead Jacks

- Additional Fit and Installation Considerations

- Exceptions to watch for

- Quick Installation Tips

- Support and Custom Drawings

- Conclusion

- FAQs

SMA Characteristics and Key Points

The SMA (SubMiniature version A) connector is one of the most widely used RF connectors in wireless communications. It is valued for its compact size, excellent electrical performance at high frequencies, and reliable threaded coupling. SMA connectors are commonly used in cellular wireless, GPS, and amateur (HAM) radio applications, while a closely related variant—RP-SMA (Reverse-Polarity SMA)—is more frequently used in Wi-Fi, Bluetooth, ZigBee, and LoRaWAN devices in the United States.

Because SMA and RP-SMA connectors look nearly identical at first glance, they are often confused or incorrectly paired. Understanding the physical, mechanical, and electrical characteristics of SMA connectors is critical to ensuring proper mating, minimizing signal loss, and preventing damage to antennas or RF devices.

SMA vs RP-SMA: A Common Source of Confusion

One of the most important distinctions to understand is the difference between SMA and RP-SMA. Although the connectors share the same threaded body dimensions, they differ internally.

- SMA uses a traditional pin-and-socket configuration

- RP-SMA reverses the pin and socket while keeping the same outer threads

As a result, an SMA connector will not electrically mate with an RP-SMA connector, even though the threads may engage. This mismatch can result in open circuits, degraded RF performance, or physical damage to the center contact.

In most cases:

- SMA is used for cellular modems, GPS antennas, test equipment, and HAM radio

- RP-SMA is commonly used for Wi-Fi routers, access points, and IoT radios in the U.S.

SMA Male vs SMA Female: Counter-Intuitive Gendering

SMA gender designation is often misunderstood because it is not based on the external threads, but rather on the center contact inside the connector body.

- SMA male (plug) → has a center pin

- SMA female (jack) → has a center socket

This is counter-intuitive because the SMA male typically has internal threads, while the SMA female has external threads. The gender is determined solely by the pin vs socket, not the threads.

Understanding this distinction is essential when selecting antennas, cables, or adapters, as incorrect gender pairing is one of the most common causes of RF connectivity issues.

SMA Connector Design and Performance

SMA connectors are round, screw-type RF connectors with medium-sized threaded coupling. They are designed to provide:

- Secure mechanical attachment

- Stable impedance matching

- Reliable RF performance at high frequencies

Standard SMA connectors are typically rated from DC (0 Hz) up to 18 GHz, making them suitable for a wide range of RF and microwave applications. Precision or extended-performance SMA variants can support even higher frequencies, but standard SMA connectors are more than sufficient for most commercial and industrial wireless systems.

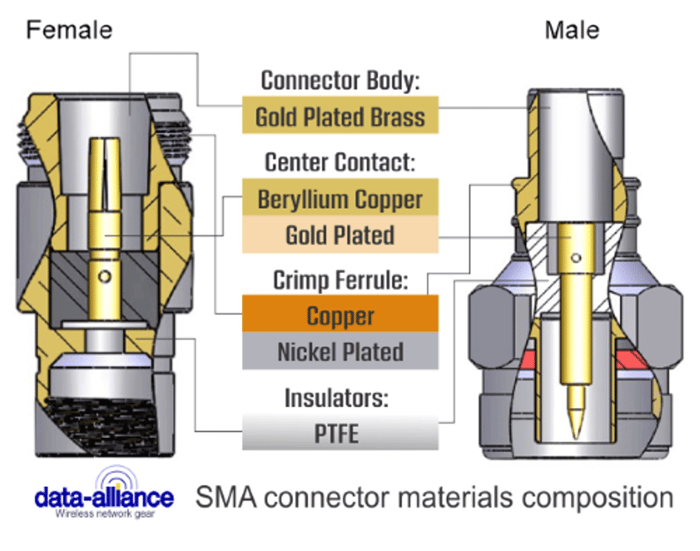

SMA Connector Materials Composition

The materials used in SMA connectors play a significant role in electrical performance, durability, and environmental resistance.

Connector Body

- Gold-plated brass

Most SMA connectors used on antenna cables are made with a gold-plated brass body. Gold plating provides excellent conductivity and corrosion resistance and is ideal for indoor applications. - Nickel-plated brass

SMA adapters and connectors expected to be exposed to moisture, humidity, or outdoor environments often use nickel-plated brass. Nickel provides enhanced protection against rust and corrosion, making it suitable for outdoor or industrial installations. - Weather-exposed SMA connectors

For antennas or cables used outdoors, nickel-plated brass is commonly chosen to balance durability and cost.

Center Contact

- Material: Beryllium Copper

- Plating: Gold

Beryllium copper offers excellent spring properties, ensuring reliable contact pressure over many mating cycles, while gold plating minimizes oxidation and signal loss.

Crimp Ferrule

- Material: Nickel-plated copper

The ferrule provides mechanical strain relief and ensures a secure termination between the connector and cable shield.

Insulator

- Material: PTFE (Polytetrafluoroethylene)

PTFE is used for its excellent dielectric properties, thermal stability, and low signal loss at RF and microwave frequencies.

SMA Male and Female Dimensions

Understanding SMA connector dimensions is essential when designing panels, enclosures, or mounting hardware.

- SMA female outside diameter:

5/16 inch (7.9375 mm)

This accommodates a hex bulkhead nut with a nominal 5/16 inch outer diameter. - SMA male inside diameter:

5/16 inch (7.9375 mm)

This refers to the internal threaded diameter of the male connector.

Panel Cutouts for SMA Bulkhead Jacks

Anti-Rotation “D-Hole” (Best Practice)

- Hole diameter: Ø 6.5 mm (0.256 in)

- Flat dimension: 6.0 mm (0.236 in) across the flat

The D-hole prevents the SMA connector from rotating during installation or when tightening an antenna or cable. Data Alliance’s default SMA connector versions include this anti-rotation D-hole, making installation easier and more reliable.

Round Hole (Common Alternative)

- Hole diameter: Ø 6.5 mm (0.256 in)

Round holes are commonly used and can work well when paired with a star or lock washer. However, they do not inherently prevent connector rotation.

Additional Fit and Installation Considerations

Thread and Nut

- SMA bulkheads use ¼-36 UNS threads

- Typical panel nut across flats: approximately 8.0 mm (5/16 in)

- Ensure adequate clearance if a socket or wrench will be used during installation

Panel Thickness

Panel thickness compatibility varies depending on bulkhead style:

- Short bulkhead versions may support a maximum panel thickness of approximately 2.2 mm (0.087 in)

- Long-thread bulkheads allow for thicker panels

Always verify panel thickness against the specific connector drawing.

Torque Specifications

- Standard SMA bulkheads: approximately 5 in-lb (0.57 N·m)

- Heavy-duty or hermetic feed-throughs: 12–15 in-lb

Excessive torque can damage threads, deform panels, or degrade RF performance, especially in plastic enclosures.

Exceptions to watch for

Not all components labeled “SMA bulkhead” use the standard 6.5 mm hole size. Certain hermetic feed-through adapters, female-to-female bulkheads, or ruggedized variants may require significantly larger holes—sometimes as large as Ø 0.500 inch.

Always confirm the exact panel cutout dimensions using the manufacturer’s mechanical drawing.

Quick Installation Tips

- Use the anti-rotation D-hole whenever possible

- For round holes, use the supplied star or lock washer

- Do not exceed the recommended torque specification

- For sealed front-mount connectors (IP67/IP68), ensure the panel finish and O-ring land meet the drawing requirements

Support and Custom Drawings

If you share the exact SKU(s) you are using, detailed customer drawings can be provided, including DXF and PDF files showing hole size, flat dimensions, and keep-out areas to simplify panel fabrication.

Conclusion

Understanding SMA connector characteristics—from gender identification and material composition to mechanical dimensions and installation best practices—is essential for building reliable RF and wireless systems. Correctly selecting and installing SMA components helps prevent mating errors, minimize signal loss, and ensure long-term performance in cellular, GPS, and industrial applications. By following proper connector selection, panel cutout, and torque guidelines, SMA connectors can deliver consistent, high-frequency performance in a wide range of indoor and outdoor environments.

FOOTNOTES:

- We offer an SMA wrench to assist in installing antennas, SMA cables and adapters with SMA or RP-SMA connector(s).

FAQs

What is an SMA connector used for?

SMA connectors are commonly used in RF and wireless systems such as cellular networks, GPS antennas, test equipment, and industrial communications. They provide reliable performance at high frequencies and secure threaded coupling.

How do I tell the difference between SMA male and SMA female connectors?

SMA connector gender is determined by the center contact, not the threads. An SMA male has a center pin, while an SMA female has a center socket, regardless of whether the threads are internal or external.

Why is SMA often confused with RP-SMA?

SMA and RP-SMA connectors look very similar and share the same threaded dimensions, but they have opposite pin-and-socket configurations. They will not electrically mate correctly, even if the threads engage.

What materials are typically used in SMA connectors?

SMA connectors are commonly made with gold-plated or nickel-plated brass bodies, beryllium copper center contacts, PTFE insulators, and nickel-plated copper ferrules to ensure good conductivity, durability, and low signal loss.

Why are proper panel cutouts and torque important for SMA connectors?

Incorrect panel cutouts or excessive torque can cause connector rotation, mechanical stress, or degraded RF performance. Following manufacturer-recommended hole sizes and torque specifications helps ensure a secure and reliable installation.

Can SMA connectors be used in outdoor or industrial environments?

Yes. When properly selected and installed—using corrosion-resistant materials, correct sealing, and appropriate torque—SMA connectors can perform reliably in both indoor and outdoor industrial environments.