W.FL Cables to SMA and RP-SMA

W.FL Cable Assemblies with SMA and RP-SMA

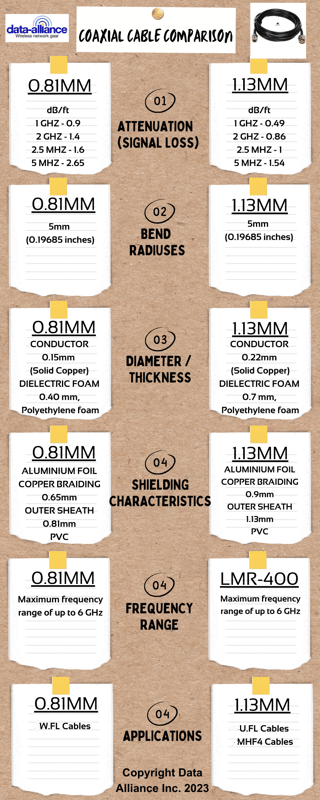

W.FL cables can only be made with the very thin and flexible coaxes such as 0.81mm. W.FL is not compatible with larger coaxes like LMR100 and RG178.

The W.FL connector is a type of RF (Radio Frequency) connector that is commonly used in various applications, including Industrial IoT (IIoT). These connectors are miniature, coaxial connectors designed for high-frequency signal transmission.

The W.FL connector is a type of RF (Radio Frequency) connector that is commonly used in various applications, including Industrial IoT (IIoT). These connectors are miniature, coaxial connectors designed for high-frequency signal transmission.

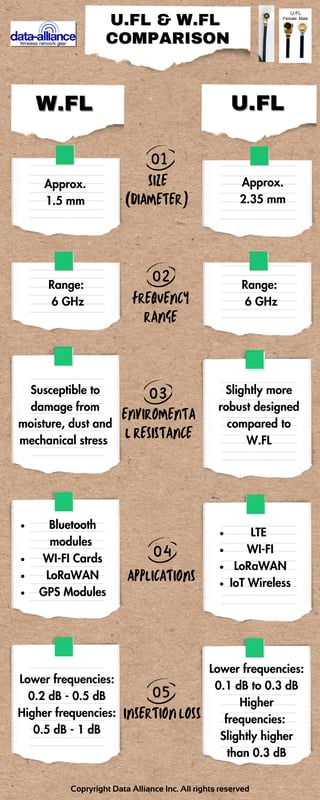

At only 55% of the size of the U.FL connector series, the W.FL Series is one of the world's smallest radio frequency connectors. This micro-miniature connector produced by Hirose is a space-saving solution for introducing wireless connectivity into densely packed electronic circuits. This short guide provides you with the essentials of W.FL connectors and cables and their common applications.

W.FL is a Micro-Miniature, lightweight coaxial connector made by Hirose Electric Group, a Japanese electronics company. It is also known as an Ultra Small Surface Mount Coaxial Connector. The connector has a frequency range of 0 - 6 GHz from DC and an impedance of 50 Ohms. W.FL occupies a mounting area of 3.4 mm square and is extremely lightweight, with a fully mated height of only 1.4mm.

W.FL connectors feature a user friendly tactile click when successfully coupled. W.FL plugs are terminated only using ultra-fine coaxial cables with fluorinated resin insulation. Termination is done using specialized tools.

W.FL connector vs U.FL connector

W.FL connectors are similar to the U.FL connector, but larger U.FL connectors mount on area of 7.7mm and weigh 15.7 mg. With both connectors, the mated height varies depending on the diameter of the coaxial cable used; W.FL ranges between 1.55mm–1.85mm, and the U.FL’s between 2mm - 2.50mm. Due to their complexity and size, these connectors have a limited mating cycle. W.FL has a maximum mating cycle of 20, and the U.FL has a maximum mating cycle of 30 times.

The W.FL connector is in many aspects a smaller version of the Hirose U.FL connector, a standard in the wireless networking industry due to its extremely small mounting area. It is used in printed circuit boards PCBs with its jack being board-mounted. The scaling down of the W.FL connector achieves a massive reduction in the board space occupied by the connector.

Physical specifications of the W.FL connector

The W.FL comprises a female plug connector and a male jack with surface mount technology (SMT) that can be mounted directly onto a circuit board. The male being placed directly on top of the female connector mates them. This is best done with a special mating and unmuting tool that ensures that the connector is properly connected and disconnected. W.FL connectors feature a user-friendly tactile click when successfully coupled. W.FL plugs are terminated only using ultra-fine coaxial cables with fluorinated resin (Teflon) insulation.

The W.FL connector has a mated height of 1.4 mm (max 1.55mm). Its mated weight is 5.6mg for the receptacle and 18.6 mg for the plug.

W.FL Plug

The W.FL plug has a right-angle orientation. It dimensions are 2.12 mm (width) by 1.38 mm (height) by 3.65 mm (length). The shell of the plug is made from silver-coated phosphor bronze and the inner receptacle is made from gold-plated phosphor bronze. The center contact is female. Within the connector, there is a small amount of polybutylene terephthalate (PBT), a semi-crystalline engineering thermoplastic, as a dielectric material.

W.FL plugs are always supplied as cable assemblies. They cannot be exchanged. It uses ultra-fine, fluorinated resin-insulated coaxial cable, as it facilitates using the connector in compact and confined environments.

W.FL Jack (receptacle)

The PCB-mounted W.FL receptacle has dimensions of 2 mm (length) by 2mm (width) and a height of 0.85 mm. Its shell is made from silver-plated phosphor bronze and its inner connector pin is made from brass. The center contact is male and is surrounded by a liquid crystal polymer dielectric. The W.FL receptacles are supplied on a tape and reel and can be located on a PCB using the vacuum nozzles of the automatic placement equipment.

The W.FL connector is minute and fragile and cannot withstand repeated connection and disconnection. It is only rated for 20 mating cycles.

W.FL connector electrical specifications

- Impedance: The W.FL connector has a nominal impedance of 50 Ohm

- Frequency range: The W.FL connector is a microwave connector that has a frequency range of DC to 6 GHz

- VSWR:. 1.3 max (up to 3 GHz) 1.4 max (3 GHz to 6 GHz)

- Contact resistance: At the center contact the resistance is 20 megohms max

- Insulation resistance: The insulation resistance is 500 megohms

W.FL cable assemblies

The thinnest cable that we can make W.FL cables with is 0.81mm (so 0.66mm is not an option for W.FL cables).

The following cables enable antennas to be connected via the larger RP-SMA or SMA connectors. The SMA connector is used for cellular, LPWAN, and GPS networking, while the RP-SMA connector is predominantly used for Wi-Fi.

- W.FL to RP-SMA-female

- W.FL to SMA-male

- W.FL to SMA-female

Applications of the W.FL Connector

With wireless devices progressively getting smaller, W.FL connectors have a wide range of applications because of their small size, low weight, and reliability at high frequencies. You will find them being used in devices that are handheld and mobile. Here is a list of common applications of W.FL connectors and cables.

- Antenna connector for Bluetooth devices

- Cellphones

- Laptops

- Data terminals

- Digital cameras

- GPS devices

- As the jack of mini-PCI Wireless cards

- Wi-Fi access points and router

- PHS

- IOT wireless instruments including sensors and actuators

The W.FL connector exceeds the more common U.FL connector in compactness and low weight. You can use it in a wide range of electronic applications where space is extremely limited.

Industrial IoT Applications of the W.FL Connector

In Industrial IoT applications, which involve the interconnection of various sensors, devices, and equipment to collect and exchange data for monitoring and control, RF connectors like W.FL connectors play a role in the following ways:

-

Wireless Communication: Industrial IoT often relies on wireless communication protocols like Wi-Fi, Bluetooth, Zigbee, LoRa, or cellular networks for data transmission. RF connectors are used to connect antennas to IoT devices to ensure efficient signal transmission.

-

Antenna Connectivity: Industrial environments can be challenging for wireless communication due to interference and signal attenuation. W.FL connectors help ensure a reliable connection between the antenna and the IoT device, optimizing signal strength and quality.

-

Sensor Integration: IoT devices may include various sensors for monitoring parameters such as temperature, humidity, pressure, or vibration. RF connectors can be used to connect RF sensors or sensor modules to the main IoT device.

-

PCB Integration: In some IoT devices, the RF connectors are used for connecting internal components, such as RF modules or transceivers, to the device's printed circuit board (PCB).

-

Space Constraints: W.FL connectors are small and compact, making them suitable for IoT devices with limited space. This is important in many industrial settings where equipment is often densely packed.

-

Ruggedness and Durability: Industrial environments can be harsh, with exposure to dust, moisture, and vibration. Some RF connectors are designed to be rugged and durable, ensuring they can withstand these conditions.

-

Signal Integrity: Maintaining signal integrity is crucial in IoT applications to ensure accurate data transmission. Properly chosen and installed RF connectors help minimize signal losses and interference.

When selecting RF connectors like the W.FL connector for Industrial IoT applications, it's important to consider factors such as the frequency of operation, the type of RF cable or coaxial cable used, environmental conditions, and the specific requirements of the application to ensure reliable and efficient data communication.

Overall, RF connectors like the W.FL connector play a vital role in enabling wireless communication and connectivity within Industrial IoT systems, helping to gather and transmit data for monitoring, control, and automation in industrial settings.