Waterproof / Weatherproof

Waterproof / Weatherproof:

IP Ratings: Ingress Protection from Water, Dust, Particles

IP rating is given as the letters IP, followed by two numerical digits whose value is determined by the level of protection provided. The higher the value the higher the protection rating.

The first digit represents ingress protection level from solids. Each value defines a certain level of protection:

0- No protection from solids.

1- Objects bigger than 50mm in width, large surface bodies such as hands.

2- Objects not larger than 80mm in long and 12mm wide, fingers and other such solids.

3- Objects with a minimum diameter of 2.5 mm, tools and thick wires and cables.

4- Objects not less than 1mm in diameter, fine tools, and screws.

5- Dust protected, sufficient dust that can cause harm to equipment.

6- Completely dustproof.

The second digit defines protection from moisture.

0- Not protected

1- Condensation and dripping water.

2- Vertical dripping water inclined at a 15 angle.

3- Spraying water, vertical spray tilted at 60.

4- Splashing water in contact with enclosure from all directions.

5- Low-pressure water jet from a 6.3mm nozzle from all directions.

6- High-pressure water jets from 12.5mm nozzle from all directions.

7- Temporally immersion in a depth of 1 Meter.

8- Continuous immersion in water under pressure.

9- 9K- close range, high-temperature jet spray from all directions.

Additional letters can be added after the digits to represent product specific protection rating. Some from mechanical impact, and access by hazardous parts, high voltage, and temperature.

IP rating (also ingress protection rating) is an international standard for classifying the degree of protection in electrical enclosures, and accessories for enclosures. Standard test environments are used to test products in compliance with manufacturer's specifications. The IP system provides detailed information on protection from physical intrusions such as dust, water, and contact. IP rating system standard is defined by IEC 60529.

Waterproofing and Weatherproofing Equipment and Accessories for Wireless Networking

Wireless connectivity is an increasingly essential part of daily life, in industrial, commercial, and domestic environments. This has increased the demand for the provision of wireless networking in a broad range of environments, often with the installation of network infrastructure outdoors. Outdoor installation of wireless equipment and other electronic and electrical devices requires consideration of how it will be housed and protected from the external environment.

Mounting electronic equipment in harsh or hazardous environments exposes sensitive components and devices to environmental factors that can rapidly degrade equipment materials and eventually impair the overall performance and lifespan of the network installation.

Without waterproof and weatherproof equipment to protect devices, many external factors will damage equipment like antennas, routers, access points, power adapters, and their associated cabling. These key environmental factors that damage outdoor networking equipment are:

[A] Corrosion

Corrosion is a naturally occurring process that degrades metals through a series of electrochemical reactions with substances in their environments. Rust is an example of corrosion and other materials like polymers can be similarly broken down. It is a progressive process that gradually destroys metal surfaces, wires, and components within electronics.

Galvanic and pitting corrosion is caused primarily by the effects of weather and in particular moisture on metals. The water molecules in moist, humid, or frankly wet environments react with electrons and oxygen on metal surfaces. Moisture will accelerate corrosion from other causes like salty marine air or corrosive chemicals such as sulfur dioxide in air pollution from high traffic or industrial areas.

Corrosion may not be discerned until electronic equipment stops working normally. It is a significant cause of costly equipment loss and network downtime Once started it cannot be stopped or reversed, therefore prevention is key.

[B] Solar radiation

Prolonged exposure to sunlight is one of the key accelerants of weathering and aging of outdoor installed equipment. Not only will intense sunlight heat an exposed object (which runs the risk of overheating, fire or shutdown), but the UV portion of sunlight breaks down plastics and other materials by a process called photodegradation. UV light can weaken and break the carbon bonds in polymers. Cracking and discoloration of plastic casings and cable jackets are a key feature of this destructive process and often expose metal components to corrosion. This decay can be marked and in an arid area may only take a few weeks or months to cause significant structural damage.

[C] Temperature extremes

Every component within an electronic device including connectors a coaxial or Ethernet cable will have a temperature rating that specifies the temperature range at which it is operable. The outdoor environment can often expose equipment to extreme hot or cold weather that exceeds these limits and leads to dysfunction and breakdown of equipment. Solar radiation, mentioned above is a big cause of outdoor equipment overheating. If the equipment is installed in an enclosure, a lack of venting or cooling to provide thermal dissipation can also precipitate overheating. A high temperature will lead to damage to key electrical components like capacitors, diodes, and the various alloys in cables and connectors. This creates the potential for burning, carbonization, and even fire.

Temperatures that are too low also affect the performance of wireless networking equipment. Extreme low temperature can cause shrinking cracking of plastics and other components and significant damage as temperatures rise and materials expand. However, temperature fluctuation or cycling proves to be a bigger problem over time rather than a constant low temperature. If electronic components are a composite of many materials (e.g. capacitors or resistors) they will likely each respond differently to the cold leading to the breakdown of the device.

[D] Moisture ingress

Waterproofing is a critical part of protecting outdoor electronic equipment because of the damaging effects of even small amounts of water that gets inside a device. Liquids, humidity, and condensation will not only cause corrosion but also will have immediate effects on the electrical circuits within the device. Moisture uptake impairs the performance of components with derangement of the dielectric constant and electrochemical migration. Positively and negatively charged ions and salts within the liquid can also affect equipment, leading to signal leakage and delay, as well as short-circuiting, which are some of the damaging effects. Electrostatic discharge precipitated by moisture can also be a fire risk.

Water vapor in the air that is in an enclosure may condense and settle on equipment if the temperature lowers, making good ventilation an important way of protecting equipment. Another point of entry is the surface runoff of rainwater via cables connected to the device.

[E] Dust and dirt

Dust is made up of solid particles that are suspended in the air. Dust is always present. It is rarely a single substance but consists of materials that include salts, minerals, inorganic, and organic substances. Dust compromises the functioning of printed circuit board assemblies (PCBAs) and other electronic components like connectors and contacts. When dust gets inside electronic equipment it can cause dielectric changes, electrical leakage, and short-circuiting. It will also raise the contact resistance of components. Dust that contains salts and ionic substances can combine with moisture to cause tarnishing and corrosion of metal components. Windblown specks of dust are a particular challenge for outdoor installations as humidity can greatly affect the particle size encountered. Inadequately protected vents can lead to dust entry into otherwise sealed enclosures. The build-up of dust on vents can also block them, causing overheating and a fire risk.

Key types of waterproofing and weatherproofing solutions for mounting electronics outdoors

There are a variety of strategies that can be utilized to protect antennas and networking devices that are installed outdoors. Many outdoor wireless components, like weatherproof antennas , are designed to withstand prolonged environmental exposure. The use of additional weatherproofing can not only enhance the longevity of a device but can also facilitate safe secure mounting and ease of access for personnel who handle the equipment.

RoHS compliant waterproofing and weatherproofing equipment for wireless networking

Our wide selection of high-performance waterproof and weatherproof equipment for outdoor network installations are fully compliant with the Restriction of Hazardous Substances (RoHS) directive and equivalent legislation. Our weatherproof enclosures, glands, and other weatherproofing are manufactured to the highest standards with materials of good quality and provenance. They also meet the requirements of the Conflict Minerals Regulation and Section 1502 of the Dodd-Frank Act. Key weatherproofing products we supply include:

Electronic enclosures are a diverse range of lidded boxes that can be used to house electronic equipment for mounting outdoor. They are also known as wireless enclosures, NEMA boxes, or electrical enclosures. They protect the equipment within them from the effects of the external environment described above and are usually specifically designed to protect equipment from impacts, temperature extremes, and the ingress of dust and moisture. Their level of protection may be rated using one of the industry-standard rating systems mentioned further on. They are available in a range of dimensions meaning that they can be precisely sized to components like routers, access points, PCBAs, batteries, and electrical junctions. They may be wall-mounted or pole mounted with the appropriate mountings and often come pre-drilled for this purpose.

Enclosures are made from either plastic or metal. If the enclosure is used for housing wireless equipment or antennas, plastic is preferable as radio frequency signals can penetrate plastics without diminishment of signal strength. Strong, rigid thermoplastics such as PVC, polycarbonate, and glass-reinforced plastic over good structural housing that resists impacts and insulates equipment over a wide temperature range. The plastics can be made UV resistant and flame retardant. Metal enclosures are typically made from steel or aluminum and protect from fire, explosions, and vandalism. Both types of enclosures are customized with different hinges, handles, and locks as well as venting and grommet-lined outlets for cabling. There are also powered enclosures that deliver mains power to an outlet on the backplate where wireless equipment is mounted.

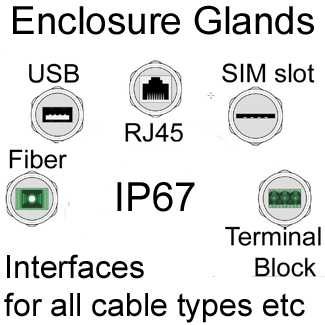

Cable glands are a key accessory for electronic enclosures and weatherproof couplings provide superior protection for connectors that are installed in an outdoor setting. They are usually quick-connect components that do not require tools or multiple steps for competent installation. Glands are bulkhead-like channels that provide a sealed conduit for the passage of cables out of connectors. Plastic glands are used for plastic enclosures and metal glands for metal enclosures. They are secured to knockouts in the enclosure wall and maintain the level of overall protection provided by the enclosure. The coupling body that is fed through the enclosure wall is secured to the wall by a locknut with a sealing nut on the other side that the cable passes through. Additional seals and gaskets provided further waterproofing to the arrangement. Gland components are not interchangeable; they should be purchased as a complete unit that is dismantled for installation. Glands are carefully sized and matched to the type of cable they carry and connectors they use.

Couplings are available for main connector types including a waterproof coupling for DC power cables. They also require dismantling so that the cable carrying the connector plug can make a sealed connection with a jack that is housed within the coupling.

Gaskets are made of silicone or rubber and create a high-performance seal on threaded components. They are a simple but effective product for improving insulation and protection from the environment and are often specified in line with rating systems like Underwriters Laboratory or NEMA.

The gasket sits between two opposing surfaces and as they are brought together, the distensible material seals the surface for an added level of protection. Gaskets may need to be replaced on bulkheads that are repeatedly connected or disconnected or where they have become worn. They are also found by the locknut or sealing nut of glands. They can be matched to components by diameter.

These are a type of connector (radiofrequency or otherwise) that has a characteristic mounting style that allows them to be readily and securely mounted on panels or be fed through the wall of an enclosure. Metal radiofrequency bulkhead connectors like the N-type bulkhead have two threaded female connectors that sit on either side of the bulkhead. One of the threaded connectors is passed through the enclosure wall and is secured to the wall by a securing nut (plus a jam nut), often with a gasket for additional sealing. At the other end, that projects into the enclosure, the antenna or cabling that is required can be securely connected.

Antennas are installed outside for a variety of telecommunications, Satcom, and industrial applications and are required to deliver reliable and consistent performance despite the challenges of operating in harsh environments. Without being fully waterproofed and weatherproofed, sensitive equipment like radio frequency antennas corrode and degrade within weeks even with relatively mild outdoor conditions and quickly become overwhelmed by moisture ingress, windblown dust, and the aging effects of sunlight. Just a little moisture within an antenna will derange the VSWR. Poor radiation patterns and deterioration of the antenna’s performance follows.

-

Weatherproof antennas come in a range of types including those for WiFi, Cellular networking, GPS, RFID, and Low Power Wide Area Networks (LPWANs) like LoRa. The resonant antenna elements of weatherproof antennas are usually well-sealed within a waterproof radome, made from weather-resistant plastics or fiberglass. The cabling used for the antenna is also selected to withstand outdoor conditions. N-connector antennas are a common choice for weatherproof antenna installation as they can be secured to mountings or enclosures securely and directly via an N-type bulkhead connector.

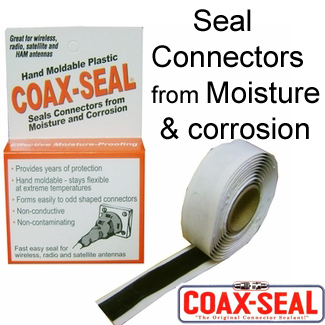

Coax sealant by Coax-Seal is the original connector sealant and an advanced solution for protecting radiofrequency connectors in outdoor installations. It is capable of protecting the connectors that are exposed outdoors for years at a time. This stretchy black tape, made of black plastic mastic, is capable of sealing a variety of cables and connector types as it impedes the ingress of moisture and the development of corrosion. It will strongly adhere to the metal of connectors as well as plastic and rubber cable jacketing and other hardware.

The tape is stretch-wrapped around the connector and cabling and then hand-molded to produce an exceptional seal. Once activated, the tape remains moldable, irrespective of whether it is hot or cold. It is non-hardening and non-oxidizing also.

If mounting an antenna at height on a roof, sealants will prevent the deterioration of metal mounting hardware by sealing them from corrosion and rust. They deliver added protection where a penetrating roof mount is used. If bolts and feet of the tripod are allowed to rust, they can bleed and create unsightly staining of paint, plasterwork, and masonry on buildings. Mastic tape pads can also be used much like roofing tar strips to seal lag screw holes and prevent water from draining through them.

Silicone grease also known as dielectric grease is made by thickening polydimethylsiloxane (silicone oil) with amorphous fumed silica. Silicone grease is available in preparations of varying thickness according to the application for which it is used. It is widely used as a waterproofing grease and sealant in outdoor networking installations.

Silicone grease can be applied liberally to O-rings, gaskets, and seals as it impedes the ingress of moisture. Unlike petroleum jelly, silicone grease carries no risk of damage to gaskets and is also able to protect threading on connectors and other components.

A great protective benefit of dielectric grease is that it is an excellent electrical insulator and can be applied to radio frequency connectors to seal and protect them. Good quality dielectric grease should remain stable over a wide range of temperatures.

Dust caps can be placed on the exposed ends of radio frequency connectors to protect them from moisture, dirt, and dust that could get into their threading and inner mating interface. They were originally metal and designed to military specifications but now are available in thermoplastic elastomer and silicone.

Many are equipped with a chain or cord to prevent the dust cap from being lost. Circular dust caps are often used to ensure that a radio frequency circuit or cable assembly maintains an adequate IP rating. They also protect the connector from physical damage and can withstand high voltages and harsh environments.

Frequently asked questions for waterproofing and weatherproofing network equipment.

What are the key ratings systems and accreditations for waterproofing and weatherproofing equipment?

Weatherproof antennas, enclosures, and other protective equipment often carry ratings or mark that specify the level of protection the equipment delivers against:

- Physical intrusion

- Ingress of dust

- Ingress of moisture

- Harm to personnel that handle the equipment

A number of our protects use these proprietary rating systems as they can help customers understand the level of protection the equipment will provide. The three key systems that are commonly encountered concerning the performance of enclosures and other weatherproofing accessories for electronics are:

[i] NEMA types

The National Electrical Manufacturers Association (NEMA) has produced a leading set of industry standards that grade electrical enclosures and their accessories. It is so widely known that even generic enclosures may be described as being “NEMA boxes”. The document NEMA 250- Enclosures for Electrical Equipment provides a detailed specification for the physical and performance characteristics of 13 types of NEMA enclosure and additional sub-types that have been developed for niche environments like mining. Key NEMA enclosure types for outdoor use include:

-

Type 3 NEMA enclosures are weather-resistant, protecting again ingress of rain, windblown dust, and dirt, as well as remaining undamaged by the formation of duct and ice on the enclosure. Type 3X is a variant that is corrosion resistant.

-

Type 4 NEMA enclosures are watertight and will withstand water sprayed under the pressure of at least 65 gallons per minute. The addition of an “X” designation means that the enclosure is corrosion resistant.

-

Type 6 NEMA boxes can withstand being submerged for either short or prolonged (Type 6P) periods. They are not designed for continuous submersion but are fully waterproof.

[ii] Underwriters Laboratories

Underwriters Laboratories (shortened to UL) is a US company that specializes in safety testings across a range of industries and Federal agencies like the Occupational Safety and Health Administration. UL-listed products comply with the organization’s stringent safety testing standards and products are either tested directly by UL or manufacturer testing is accredited by them. For consumers, the UL brand assures that the enclosures are high performance and will function as described.

UL publishes several standards that deal with electrical enclosures and their accessories including UL 50, UL 50 E, UL 94, and UL 508. They are broadly comparable to international rating standards developed by the International Electrotechnical Commission (IEC).

[iii] Ingress Protection Codes

Ingress Protection Codes, also known as IP Codes are a concise system of ratings for weatherproofing equipment that detail the level of protection they provide primarily against physical intrusion or dust, moisture, and liquids. They have been developed by the IEC and are also related to the equivalent EU standard 60529. The code consists of two digits and can include up to two supplementary letters to add additional detail to the rating.

-

The first digit deals with protection against dust and ranges from “X”, which means that there is no rating to 6 which means that a component is dust-tight.

-

The second digit specifies protection against moisture ingress and ranges from “X”, meaning that there is no rating to 8 which means that the component resists the ingress of moisture when immersing to over 1 meter in depth for over 30 minutes.

How should I position my wireless access point or router outdoors?

The location of routers and access points that are installed outdoors is critical to the performance of the wireless network you intend to build. Wireless networking infrastructure needs to be properly planned as wired network components will be needed to be connected to the access point and router so that devices can access the router’s wireless signal.

Routers and APs need to be positioned to provide the maximum coverage in the desired area. For outdoor installation, multiple routers may be needed and so will have individual environmental challenges (e.g. solar radiation, dripping water, windblown dust). Using an enclosure means that a consistent standard of protection is provided to the router even if it is itself outdoor rated.

-

Locate your outdoor router where your wireless network has a high demand.

As much as is possible the router should be positioned in proximity to where devices will use it as the quality of the signal will be better. Seated or lawned areas, or where a wireless device is also installed are advantageous.

-

WiFi survey software can be used to precisely position a router outdoors.

Precision placement of a router of AP will produce the best signal strength where required. WiFi survey tools and software can be installed on a laptop for a site survey.

The location chosen should, as far as possible comply, with specifications delivered by the manufacture of the wireless equipment.

-

If installing multiple routers, avoid overlap of their coverage.

Increasing the number of routers installed outdoors does not necessarily improve network performance. It may be difficult to avoid in condensed areas of a property. If too many routers are installed or they are too close to one another this can cause coverage overlap with interference due to channel overlapping and increased collisions. A proper WiFi site survey and channel planning will help you pinpoint the optimal placement for routers and AP for good coverage without channel overlap.

-

Avoid hazards and obstructions.

When wall-mounting or pole-mounting a router outdoors care must be taken for serious hazards that may be encountered by the installer or personal who handle the wireless enclosure. Never mount an AP or router near overhead powerlines, tree branches, or telephone cables (powerlines are often mistaken for these).

Sources of electromagnetic interference and signal, reflections, multipath, and attenuation are also disadvantageous. Avoid installing your outdoor router near bodies of water, dense foliage, obstructing buildings, and other devices that emit electromagnetic radiation. Dense building materials like concrete and metal can also block a wireless signal.

-

Be prepared to adjust positioning if needed.

Once you have found a provisional position for your router, use signal strength testing to see if it will be adequate for your requirements. If not, the enclosure can be positioned elsewhere. One of the key advantages of mounting a network router inside an outdoor enclosure is that the router is installed within the NEMA box, meaning you just have to move the enclosure rather than the sensitive equipment that could become damaged during the transfer.

- Use outdoor-rated Ethernet cable and coax to set up your outdoor wireless network.

If the cable used is not outdoor rated, the cable will have a severely shortened lifespan and could cause corrosion to track into the enclosure. Cable glands and connector couplings also protect your installation.

In conclusion

Using high-quality waterproofing and weatherproofing equipment and accessories to protect your wireless networking equipment is a critical investment for outdoor infrastructure. This diverse range of solutions is suitable for housing and protecting outdoor network installations on any scale.

LEARN MORE: